FAQS

WHAT IS MEANT BY EPAL MARK

The EUR brand pallet is a handling tool whose characteristics were first conceived in the 1950s. Suitable for the needs of the market, it spread very quickly. But, as all the countries involved did not strictly apply the same control rules in production and repairs, the pallet stock tended to become heterogeneous. A non-uniform quality, in fact, no longer allowed to guarantee the correct exchange across borders: this is why the EPAL was created.

The EUR brand pallet is a handling tool whose characteristics were first conceived in the 1950s. Suitable for the needs of the market, it spread very quickly. But, as all the countries involved did not strictly apply the same control rules in production and repairs, the pallet stock tended to become heterogeneous. A non-uniform quality, in fact, no longer allowed to guarantee the correct exchange across borders: this is why the EPAL was created.

Thus the European Pallet Association e.V. was established. (EPAL), a non-profit European association (under German law), founded in 1991 by pallet professionals (manufacturers, repairers, traders) and railway managers from three European countries: Germany, France and Switzerland. The EPAL System, through the establishment of the first National Committees, became operational on 1 January 1995 with the primary aim of guaranteeing the quality standard (technical specifications UIC 435/2 and UIC 435/4) of the EUR 800 x 1,200 mm pallet by promoting its exchange and dissemination. The EUR EPAL pallet park contributes greatly to trouble-free handling of goods traffic while applying very strict quality controls. EPAL marks the EUR pallets it inspects with the abbreviation EPAL, guaranteeing the absolute quality of the EPAL certified EUR pallets.

SHRINKAGE OF WOOD AND ANISOTROPY

Anisotropy is the property for which a certain material has characteristics that depend on the direction along which they are considered. This is therefore called anisotropic if its physical characteristics (electrical and thermal conductivity, optical properties) or its mechanical behavior (stiffness, resistance, toughness) are different in longitudinal and transversal directions.

Wood is also an anisotropic material as its dimensional variations (shrinkage, especially) vary according to the direction considered:

• longitudinal shrinkage < 0.1% – transversal shrinkage between 1 and 10% – radial shrinkage = 5% – tangential shrinkage = 10% The dimensional variations of wood are mainly due to humidity, considering that it can contain a quantity of water greater than 100% of its own dry weight and to a lesser extent by the temperature.

ISPM 15 – FAO (INTERNATIONAL STANDARDS FOR PHYTOSANITARY MEASURES NO.15)

FAO announced on 18 March 2002 in Rome that some 90 countries have approved new guidelines on wood packaging materials, which acknowledge the possible introduction and spread of harmful organisms through packaging materials composed of raw unprocessed wood. According to FAO, these organisms pose a non-negligible threat to living trees.

The directives, adopted by the Commission for sanitary measures (ICPM – Interim Commission on Phytosanitary Measures) of the International Plant Protection Convention (CIPV- International Plant Protection Convention – IPPC) have been formulated to try to harmonize the different national regulations on wood packing materials.

This is due to the fact that, for example, the USA has recently imposed quarantine measures aimed at preventing the introduction of the “Asiatic cerambycidal beetle” via wooden packaging materials from China. China has introduced its own treatment and documentation requirements for wooden packaging from the USA that could harbor the “pine nematode”. The European Union has therefore adopted a series of regulations to control the “nematodes” contained in coniferous wood packages from both the USA and China, and others still according to their specific needs.

According to FAO, the ultimate goal is not only to protect forests from imported pests, but to enable free world trade as wood packing material, in the form of pallets, crates, crates or stowage, it is used in approximately 70% of all transnational shipments. To ensure that the packaging material is free from harmful organisms, exporters will therefore have to certify, with a universally recognized symbol, that the material has been treated.

HOW THE THERMAL TREATMENT IS CARRIED OUT (MARKING: HT OR HEAT TREATMENT)

The wood packaging material is heat treated following a specific program according to which the internal temperature of the wood must reach at least 56 °C for the minimum duration of 30 minutes on the entire profile of the wood (including its central part). Different energy sources or processes can be suitable to obtain these parameters. For example, kiln drying, chemical pressure impregnation, microwave or other treatments can be considered heat treatments, provided they meet the HT requirements described in the standard.

HOW THE HT MARK LOOKS LIKE AND HOW THE MARKING IS CARRIED OUT

Hot stamping is generally used to mark wood, PVC, ABS, plastic, leather, etc. There are various powers expressed in kW that best suit the material to be printed, it is therefore possible to prepare plates with letters and / or logos in order to be able to imprint the desired wording.

Hot stamping is generally used to mark wood, PVC, ABS, plastic, leather, etc. There are various powers expressed in kW that best suit the material to be printed, it is therefore possible to prepare plates with letters and / or logos in order to be able to imprint the desired wording.

The mark indicating that wood packaging material has undergone an approved plant protection treatment includes the following mandatory components:

• ear symbol

• country code

• code of the producer/company supplying the treatment

• treatment code using the specific abbreviation as prescribed in Attachment 1 (HT or MB).

HOW TO AVOID THE PRESENCE OF MOLD ON WOODEN PACKAGING

Mold can grow on any moist surface in dim light and warm temperatures. Freshly sawn (damp) wood is a material that lends itself to the attack of molds even if heat treated (HT) consequently it is advisable for user companies to complete the heat treatment with the drying cycle in case of commercial need.

We would like to underline that the drying of the wooden packaging is an added value to the packaging itself (for example it is more stable in terms of dimensions and deformation than the fresh one) and that to obtain a wood humidity equal to 18 % it is necessary to leave the material in the drying cell for 36/72 hours compared to 6/12 hours of the ISPM-15 heat treatment. It is evident that the drying operation of the packaging has an impact on the final cost of the packaging (however, dried wood does not offer the favorable conditions for an attack by fungi/molds).

WHAT IS CONAI

CONAI (National Packaging Consortium) is the private consortium made up of packaging producers and users with the aim of pursuing the objectives of recovery and recycling of packaging materials. Membership in Conai is mandatory for companies that produce, sell or use packaging. The Conai environmental contribution, established for each type of packaging material, represents the form of financing through which Conai distributes the costs of separate collection, recycling and recovery of primary packaging waste between producers and users (for the sale ), secondary (multiple sales unit grouping packaging) and tertiary (transport packaging). These costs are determined on the basis of the general program for prevention and management.

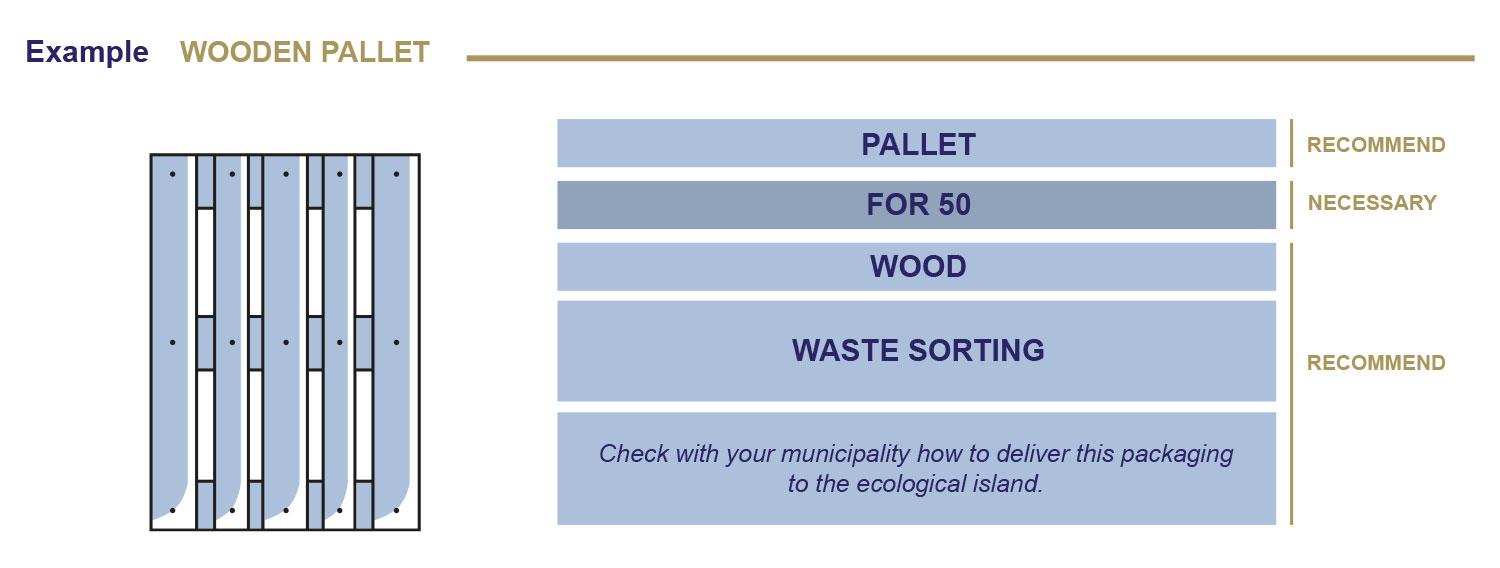

ENVIRONMENTAL LABEL FOR WOODEN PACKAGING

The Decree n. 360 of 28 September 2022, “Guidelines on the labeling of packaging pursuant to art. 219, paragraph 5, of legislative decree 3 April 2006, n. 152” contains the operational indications on packaging starting from 1 January 2023 . As in other similar situations, everything that has already been placed on the market and is not compliant, or already produced and not confirmed, can be sold and circulated until stocks run out.

The Decree n. 360 of 28 September 2022, “Guidelines on the labeling of packaging pursuant to art. 219, paragraph 5, of legislative decree 3 April 2006, n. 152” contains the operational indications on packaging starting from 1 January 2023 . As in other similar situations, everything that has already been placed on the market and is not compliant, or already produced and not confirmed, can be sold and circulated until stocks run out.

The Decree adopts the Guidelines drawn up by Conai and in part already applied by numerous companies and distinguishes according to the recipients: consumers-citizens and economic operators.

According to the indications provided by the Ministry, it can be seen that “packaging intended for commercial/industrial channels, as reported on page 18 of the Guidelines, (including pallets, industrial packaging and fruit and vegetable packaging) can report the requested information only on the transport documents, as already anticipated in recent months. And the only information required in the case of packaging intended for the commercial/industrial channel is to indicate (in the transport documents) the identification code of the material (ie FOR 50 for wood).

In the case, however, of packaging intended for the consumer (mostly cork stoppers or wine crates), two types of information are required: the separate collection method and the identification code of the material (FOR 50 for wood, FOR 51 for the cork). And this information must be reported on the packaging.

As an alternative to physically affixing this information to the packaging, it is possible to make it available through digital channels of your choice (e.g. apps, QR codes, websites). If digital channels are used, the instructions for intercepting the mandatory information described above must be made easily known and accessible to the user.”

In the indications of the colors allowed for the labeling of packaging intended for the final consumer, the indication of color for wood is not foreseen. Since these are small packages (whether caps or trays), from a technical point of view it is justified that they go to the organic fraction, while in the case of crates for fruit and vegetables or for wines, the route is the one indicated from time to time by the Municipality in where we are.